What is air bearing technology?

Air bearing technology uses a thin film of air to support a moving part and reduce friction, offering an alternative to traditional roller or ball bearings that rely on mechanical contact between parts. By pumping air through small holes in the bearing, a uniform air film is created between the bearing and the moving part. This air film separates the two surfaces, significantly reducing friction and allowing for smooth and precise movement.

Advantages of air bearing technology

Air bearings offer several significant advantages. One of the primary benefits is their ability to absorb and dampen vibrations, leading to smoother operation. The low friction provided by the air film allows for higher operational speeds, making air bearings suitable for high-speed applications. Additionally, air bearings do not require lubrication, making them ideal for turntables. The absence of direct contact between moving parts means that friction is significantly reduced, leading to minimal wear and increased lifespan of components. Furthermore, air bearings can achieve extremely high precision and stability, giving turntables finely tuned and accurate movement.

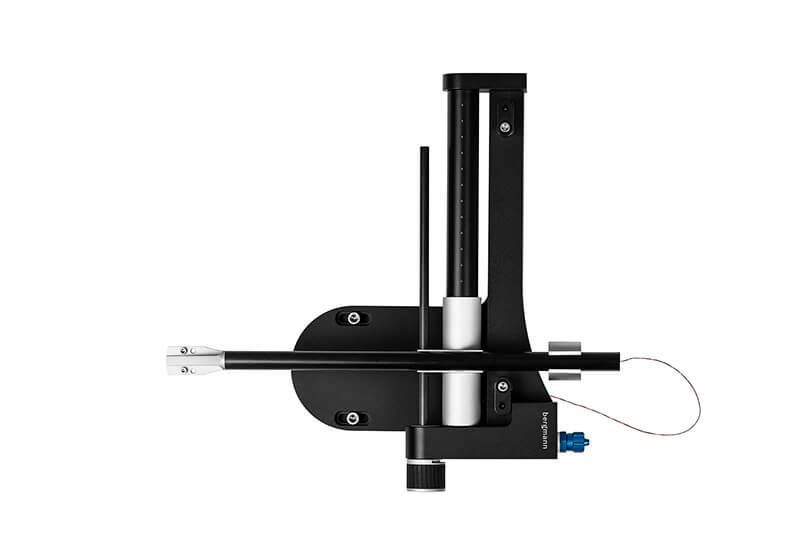

Odin

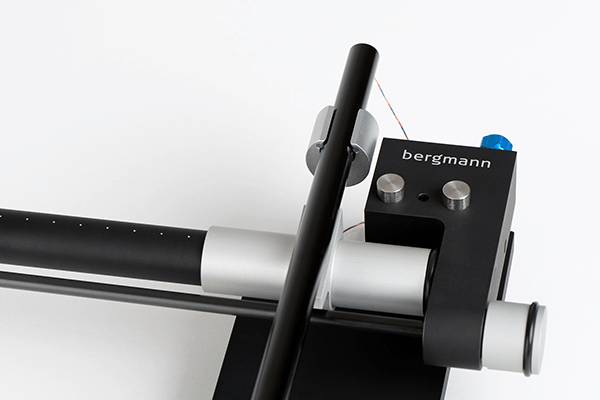

The most universal linear tracking

air bearing tonearm

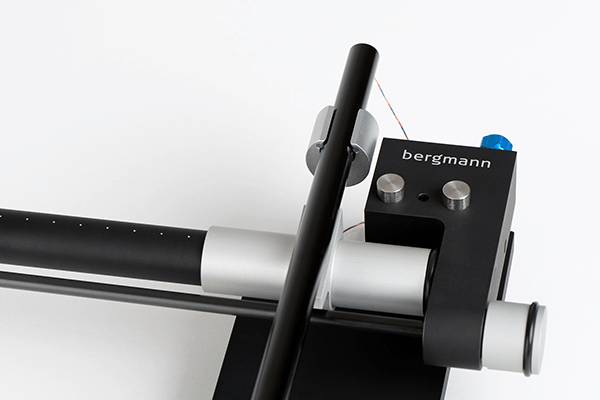

Air bearing tonearms

Enhanced tracking accuracy

Air bearing tonearms offer exceptional tracking accuracy. Traditional tonearms often encounter friction and mechanical resistance, which can cause slight deviations in the stylus’ path as it moves along the record grooves. Air bearing tonearms eliminate these issues by using a cushion of air to support the tonearm, allowing it to float and move with minimal resistance. This ensures precise tracking and better sound reproduction.

High-End cartridges

Air bearing tonearms are often compatible with high-end cartridges, which are designed to provide the best possible sound quality. The precise and stable nature of air bearing tonearms allows these cartridges to perform at their best, extracting maximum detail and fidelity from the record grooves.

The air bearing allows for smooth and effortless movement of the tonearm, that will glide seamlessly over the record. This effortless movement ensures that the stylus maintains consistent contact and improving overall playback quality.

Superior sound quality

By minimizing friction, resonance, and vibration, air bearing tonearms contribute to superior sound quality. The stylus can follow the record grooves without interference, capturing more detail and nuance in the music. This leads to a more transparent and lifelike audio reproduction, enhancing the listening experience, making them an excellent choice for high-end record players, providing an exceptional listening experience for audiophiles as well as newcomers.

Air bearing platters

Reduced vibration and noise

One of the primary benefits of air bearing platters is their ability to significantly reduce vibration and noise. Traditional record player platters can transmit vibrations from the motor or the environment to the stylus, affecting sound quality. Air bearing platters use a cushion of air to isolate the platter from its base, minimizing vibrations and ensuring a smoother, more stable rotation. This results in a clearer and more accurate sound reproduction.

The low friction environment created by air bearings allows the platter to achieve and maintain high speeds with greater ease.

Precision and Stability

Air bearing technology provides a high level of precision and stability to the platter’s rotation. The uniform air film created by the air bearing ensures that the platter remains perfectly level and rotates with minimal deviation. This precision is crucial for maintaining consistent speed and pitch, thereby improving the fidelity of the audio playback. The reduced friction and absence of mechanical noise ensure that the stylus picks up only the audio signal from the record grooves, without any interference. This results in a purer and more detailed sound, capturing the nuances of the music more effectively.

Durability

With air bearings, there is no direct mechanical contact between the moving parts. This lack of contact reduces wear and tear on the platter and bearing components, significantly extending their lifespan. Traditional bearings can wear down over time, leading to increased friction and reduced performance. Air bearing platters avoid this issue, maintaining their high performance over extended periods.

As air bearing platters do not require lubrication, unlike traditional mechanical bearings. This clean operation is beneficial for maintaining the integrity of the record player and preventing contamination of the records. The absence of lubricants also means that there is no risk of attracting dust or debris, which can affect the playback quality.

Airsupply for air bearings

The Bergmann air supply

The air supply has been the object of our greatest attention. The goal is to design a silent air supply, which could be placed in the listening room, and deliver an even, clean and dry air flow.

The pump is an oil free, long life unit, which do not require much maintenance.

The impulses from the pump are absorbed in an encapsulated reservoir. This results in an even airflow to the air bearing.

No dust

The airsupply is equiped with condence- and replaceable dustfilters, and reservoirs to obtain dry, clean and smooth airflow. Further more the air supply is so noiseless, that it can be placed in the listening room.

Unique airflow

The Bergmann Audio air supply for air bearing technology offers a precise and consistent airflow, ensuring optimal performance and stability of air bearing components. This results in reduced vibrations, enhanced sound quality, and prolonged lifespan of the equipment, making it an ideal choice for audiophiles seeking high-fidelity audio reproduction.

Bergmann air bearing turntables and linear tracking airbearing tonearms

Experience unparalleled audio fidelity with the Bergmann air bearing turntable and tonearm combination. Utilizing cutting edge air bearing technology.