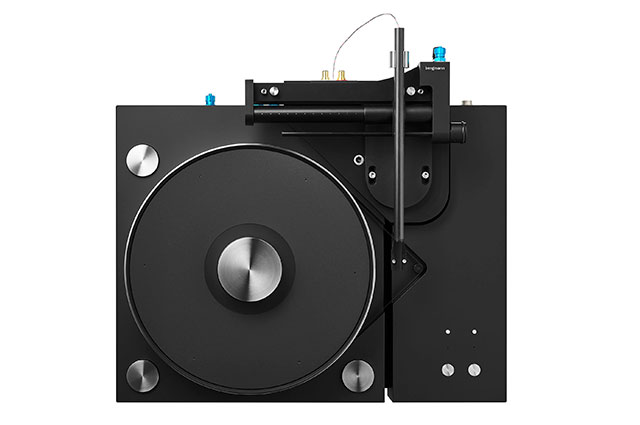

Galder-Odin Signature

Danish design – produced in Denmark

In 2022 it was 5 years since we launched the well-known classic Galder & Odin, which, from the beginning, has won great acclaim – for design, technology, craftsmanship, ease of use, and not least the sonic qualities.

With the Galder-Odin Signature, we have taken this system to a new sonic level.

Advantage of using air bearings

The platter is centered by a steel spindle, running in a very frictionless, low noise and hard wearing polymeric bearing material, and floats on a thin air cushion, which lower the mechanical bearing noise to an absolute minimum- if any. (A traditional bearing solution, which keep the platter centered AND support the platter weight, makes a higher level of mechanical bearing noise, as the contact point between spindle top and platter, generates a very high pressure – and hereby noise.)

By floating on an air cushion, the platter also gains the advantage of a very good isolation from the surroundings, same way as the known -and very expensive- air supported shelfs, used in many highend audio systems.

Also the speed stability benefit from the air supported platter. The musical flow is really extraordinary – not necessarily measurable but audiable.

Turntable and tonearm system.

Airbearing design.

Vacuum hold down.

Accept 2 additional tonearms. All tonearm designs, radial – and linear tracking.

Plinth:

Black-coated die cast aluminum.

Platter/Bearing:

A 2-piece stainless steel platter floats on air. 3mm acrylic mat.

Centered by hard anodized spindle/hardwearing low friction polymer bearing.

Platter weight:

36 kg.

Feet:

Adjustable feet. Stainless steel/ceraball construction.

Dimensions

365 x 480 x 190mm (D x W x H)

Total weight:

61.0 kg.

Motorbase:

Tacho motor with high precision feedback control system.

33 & 45

Belt driven

Tonearm:

Linear tracking airbearing tonearm.

Aluminium/carbon.

Armtube damped inside.

Counter weight decoupled from armtube.

Adjustments: VTA, overhang azimuth, levelling. Tracking force.

Wire:

Pure copper litz.

Clips:

Gold plated copper.

Connectors:

Gold plated RCA or DIN.

Effective mass: 14g.

Airsupply:

Silent, clean, dry and smooth airflow. Replaceable filter.

Easy accessible dust filter, for easy cleaning and replacement.

Dimensions:

390 x 420 x 210mm. (D x W x H)

Weight:

30 kg.

With the Galder-Odin Signature, we achieve even more depth and weight in the low frequencies. The transparency is dramatically improved, and the full sound image has become even more vivid.

A pleasure for the ear – and the eye.

The plinth is made of one solid piece of CNC-machined die-cast aluminum, as well as the motorbase. Both parts with Black Velvet painted finish. The plinth is securely tightened to a 10mm aluminum bottom plate, which is standing on 3 adjustable feet.

The feet is stainless steel and ceramic ball construction. 3 upper and smaller ceramic balls configured in a triangle, is standing on top of one bigger lower ceramic ball. No matter the feet’ position, the 3 upper ceramic balls will always have perfect contact to the lower ceramic ball.

The motor base is standing on the aluminum bottom plate –but decoupled – and will always be aligned with the plinth, no matter the feet’ position.

On the back side of the plinth, the back panel is mounted. It consists of: Grounding, Air input, Vacuum input, output for the Odin Signature air-bearing tonearm, and air adjustment valves for the platter and tonearm.

The motorbase on Galder is equipped with a DC tacho motor. Communication between the tacho and the high precision motor control electronic, will keep the platter in a very accurate speed. We measured 0.0027% speed variation!

The power supply for the motor control electronic, is build into in the air supply box, to keep high voltage distant from the inter connects delicate signal transmission. Connection is by a 5 meter cable with M-12 connectors.

The air supply is remote controlled from the motorbase. By pressing ether 33 or 45 rpm, first press the air supply goes “ON”, and second press the platter starts to spin. When turning “OFF” the selected speed, the air supply goes “OFF” automatically after 2 minutes. Very user friendly and convenient.

The air supply has been the object of our greatest attention. The goal is to design a silent air supply, which could be placed in the listening room, and deliver an even, clean and dry air flow.

The pump is an oil free, long life unit, which do not require much maintenance.

The impulses from the pump are absorbed in an encapsulated reservoir. This results in an even airflow to the air bearing. The air supply is mounted with a filter, which prevents dust particles in entering the system. This filter is replaceable when necessary.

There are different way to flatten a record, and secure that the record have a good contact to the record mat/platter. A clamp covering the record label, will only keep the center of the record perfectly flattened. A metal ring, on the outer edge will only keep the outer part of the record flattened. The only way to flatten the record completely, is by obtaining a vacuum between the record and the mat/platter – vacuum hold down. The vacuum hold down invented by Bergmann Audio, is the most user friendly system. The vacuum pump – which is in the air supply box – doesn’t need to be turned “OFF”, when changing record. The user simply remove the vacuum clamp that is covering the center spindle, and the vacuum is released, and the record can easily be changed while the platter is still spinning.After changing the record, put back the vacuum clamp, and the record is automatically flattened by the vacuum hold down system.

Then linear tracking tonearm tracks the record as it is pressed = no tracking error.

The benefit is a distortion-free and relaxed reproduction, even at complex passages.

One more important advantage of the airbearing is the tonearm`s immunity to acoustic feedback, as it has no mechanical contact (the moving part) to the turntable. The only contact is through the stylus tip and the tonearm wire.

Timbre, details and nuances, is a natural part of the transparent and vivid acoustic image