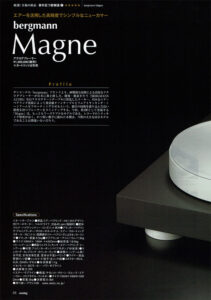

By Yutaka Suzuki

Bergmann Magne

Bergmann Magne is an advanced analog turntable system that uses a unique air bearing technology to float a heavy turntable and a linear tracking tonearm, providing an ideal environment for achieving tracking accuracy of analog disc records. The turntable platter has a double structure with a 1.5 kg sub-platter inside a 5.5 kg main platter made of precision-machined aluminum. It is precisely belt-driven by a servo-controlled DC motor. This platter assembly weighs a total of 7 kg, and the center spindle is completely floated by compressed air sent from the air supply unit, eliminating frictional resistance to the utmost.Bergmann_Magne-_mix2

Air from the air supply is also sent to the arm pipe separately from the platter, and quietly blows out from a tiny outlet opened in the pipe.

The sliding pipe, which has an inner diameter one size larger than the arm pipe, is completely floated concentrically with respect to the arm pipe, eliminating contact and eliminating friction loss. It is an innovative mechanism that eliminates all factors that hinder the smooth movement of the linear tracking tonearm, which is required to move at right angles to the cartridge needle tip.

Why air? – The air bearing mechanism in the turntable is unmatched by other bearing solutions in terms of the banishment of bearing noise and rotational stability due to its extremely small friction coefficient. The air bearing mechanism in the tonearm is extremely ideal, especially for linear tracking tonearms. The linear tracking system covers all the weak points of the swing arm and has the potential to pick up the sound groove in a straight line and accurately over the entire circumference, just like a cutting machine, but its movement is subject to strict constraints. The tonearm must remain stationary against the complex audio signal engraved in the sound groove, allowing the cartridge needle tip to move freely and sensitively. However, on the other hand, it must move smoothly without resistance against the gentle movement of the sound groove. The frictionless arm movement brought about by the air bearing is the only solution.

The floating of the turntable and tonearm by this air bearing mechanism, which eliminates mechanical contact to the utmost extent, provides overwhelmingly superior frequency response compared to other linear tracking methods, realizing clear transient response and weighty low-frequency response that reproduces natural sound images. It accurately picks up the information engraved in the sound groove, providing a high ability to reproduce the details and nuances of the sound without any loss.